1.Whole machine controlled by central PLC control system with man-machine.

More stable performance, easy for operation and maintenance. Chinese and

English interface language can be shifted easily.

2.Constant auto-tension control for unwinding, LPC edge alignment, AC inverter

constant speed auto material feeding.

3. Imported double servo-motor material dragging control system

4.Main motor for up-down sealing and pressing equipped with inverter.

5.PID for sealing bar temperature adjustment, no touch auto control, centralized

setting in man-machine interface.

6.Equipped with Pneumatic multi-function auto punching device, trim cutting and

auto rewinding and static eliminator

7.Temperature adjustment range: 0~ 300C

8.Counter: quantity, batch accumulation, pre-set available.

9.0peration Method: by length fixation control and/or by photocell tracking control.

10.Punching device: working rhythm can pre-set as continuous, interval or stop,

punching time can be pre-set.

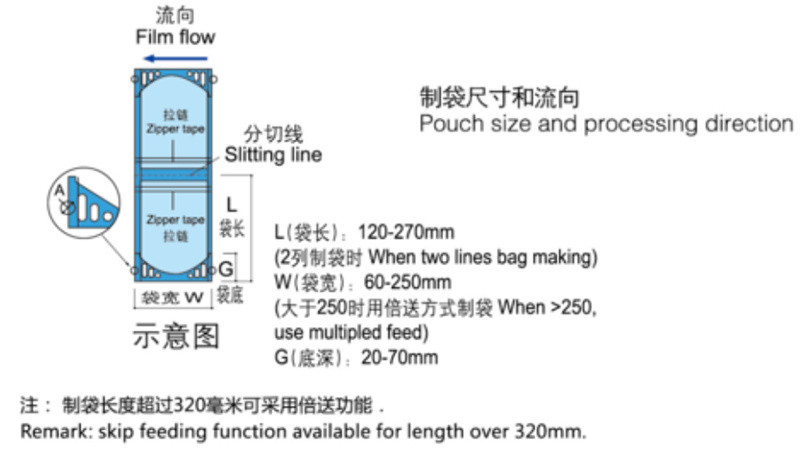

11.Material Skip Feeding: one to six times available.

12.Batch Conveying Function available, the quantity of batch can be preset.

|

Type

|

ES-E400

|

ES-E500

|

|

Max.Diameter of Roll Material

|

600mm

|

600mm

|

|

Max.Width of Roll Material

|

850mm

|

1250mm

|

|

Max.Width for Accessorial Material

|

160mm

|

160mm

|

|

Max.Speed

|

150段/min(pieces/mm)

|

150段/min(pieces/mm)

|

|

Max.Mechanical Speed

|

约(Approx.)35米/分

|

约(Approx.)35米/分

|

|

Max.Bag-making Width

|

600mm

|

600mm

|

|

Bag-making Length

|

50-2400mm

|

50-2400mm

|

|

Total Power

|

55Kw

|

65Kw

|

|

Weight of Machine

|

6500kg

|

7500kg

|

|

Overall Dimension

|

L12500xW2300×H1870mm

|

L12500×W2500×H1870mm

|