1.Whole machine controlled by central PLC control system with man-machine.

More stable performance, easy for operation and maintenance. Chinese and

English interface language can be shifted easily.

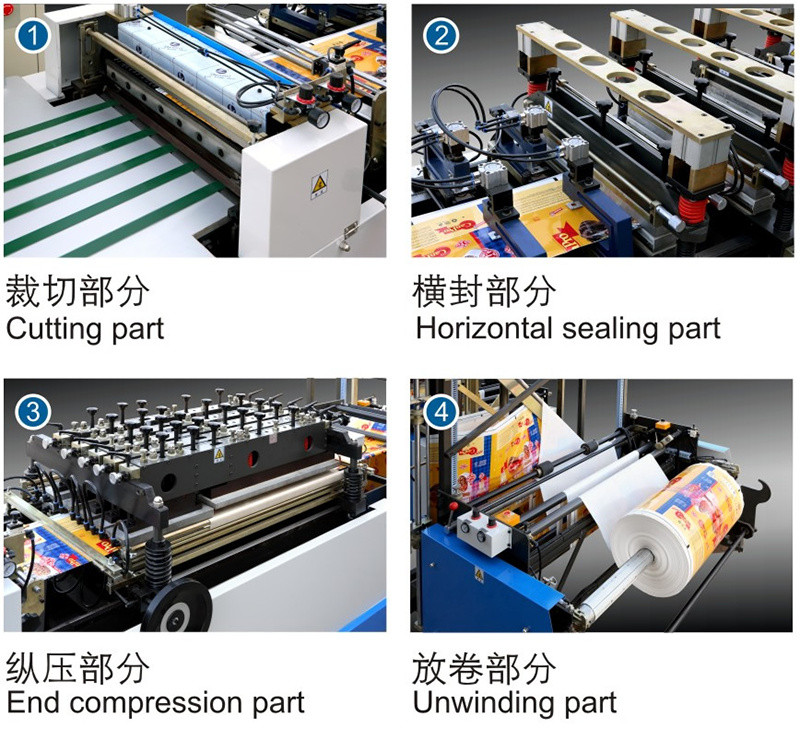

2.Constant auto-tension control for unwinding, LPC edge alignment, AC inverter

constant speed auto material feeding.

3. Imported double servo-motor material dragging control system

4.Main motor for up-down sealing and pressing equipped with inverter.

5.PID for sealing bar temperature adjustment, no touch auto control, centralized

setting in man-machine interface.

6.Equipped with Pneumatic multi-function auto punching device, trim cutting and

auto rewinding and static eliminator

7.Temperature adjustment range: 0~ 300C

8.Counter: quantity, batch accumulation, pre-set available.

9.0peration Method: by length fixation control and/or by photocell tracking control.

10.Punching device: working rhythm can pre-set as continuous, interval or stop,

punching time can be pre-set.

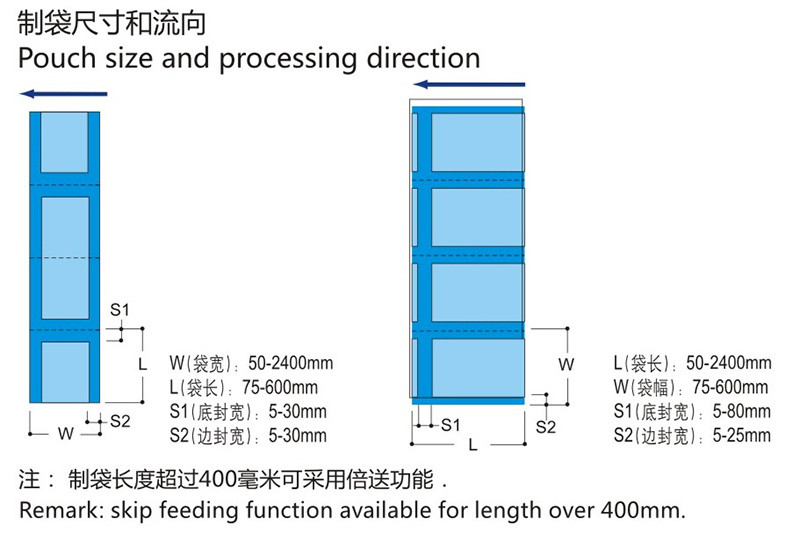

11.Material Skip Feeding: one to six times available.

12.Batch Conveying Function available, the quantity of batch can be preset.

|

MAIN TECHNICAL VARIABLES

|

|

Type ES-A400 ES-A600

|

|

Max.DiameterofRollMaterial Ф600 Ф600

|

|

Max.WidthofRollMaterial 850mm 1250mm

|

|

Max.Speed 160段/min 160段/min

|

|

Max.MechanicalSpeed 40米/min 40米/min

|

|

TotalPower 35KW 45KW

|

|

WeightofMachine 4000kg 5000kg

|

|

OverallDimension 9000×1800×1870mm 9000 x2000×1870mm

|

|

|

|

Remark:Real operation speed is variable due to diferent pouch shape.material and size.

|