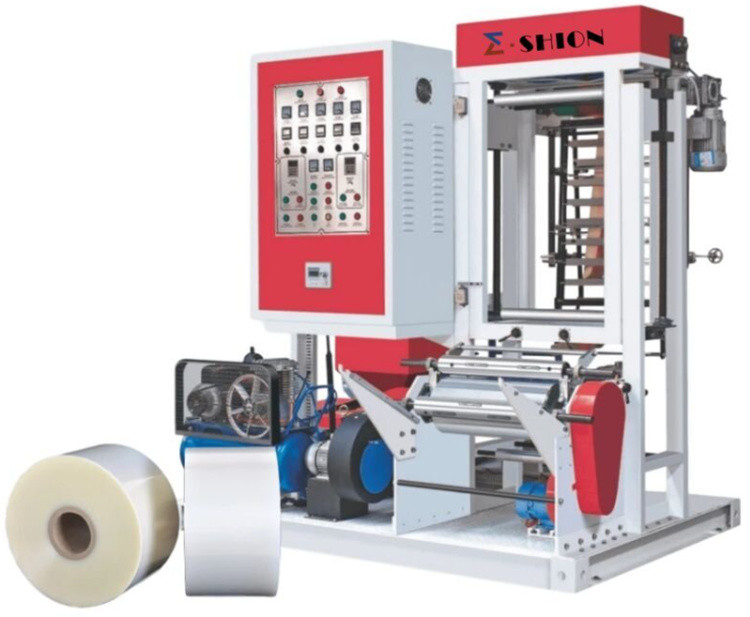

It applies to blow various LDPE, HDPE and LLDPE plastic film, widely applying to food, fruit, clothing, textile, vest type bag and etc. Packing of civil industrial products.

1. Main motor and take-up motor speed adjust by inverter. (Winder part has inverter control)

2. By pneumatic cylinder system to adjust the gap of take-up roller and embossing roller

3. Equipped with A-FORM wooden board to make the gusset, and the embossing roller.

4. Material of screw and barrel: 38CrMoAlA Polished with Nitrided Treatment Hardness of heat treatment: screw HV≥740, barrel HV≥900,Depth of hardening:0.6-0.7mm,Brittleness grade: ≤2 grade

5. Gear box: Surface heat quenching and tempering/auto. Oil lubricated

6. Die material: Steel 40rMu surface treatment of flow channel: hardchrome- plating

7. Digital display temperature controller

8. Air compressor included

9. Die head is fixed type with Al air rings

10. Single winder with two station rollers

11. Lift traction

12. All motors have gear box, except the lift traction motor.

It applies to blow various LDPE, HDPE and LLDPE plastic film, widely applying to food, fruit, clothing, textile, vest type bag and etc. Packing of civil industrial products.

The Line applies extrusion system made of special steel, high precision die head,(optional reversing die head)automatic precise temperature controller,contact-free solid-state relay and other famous national brand electronic parts.

This kind of film is widely used in liquid film, pearl film,composite base film, heat shrinkable film, tire separation film, anti-aging multifunctional film, anti-interference film, impermeable film, stretch film, cable film, etc.

This machine is used to blow various low-density polyethylene(LDPE) and high-density polyethylene (HDPE) color strip plastic films. The plastic films can be widely used for making two colors table cloth film .